Avoiding Voids

An All-Encompassing Solution.

Along with the

very convincing

of Convergence-Pad

Soldering, this also

effects another finish

inside a connection.

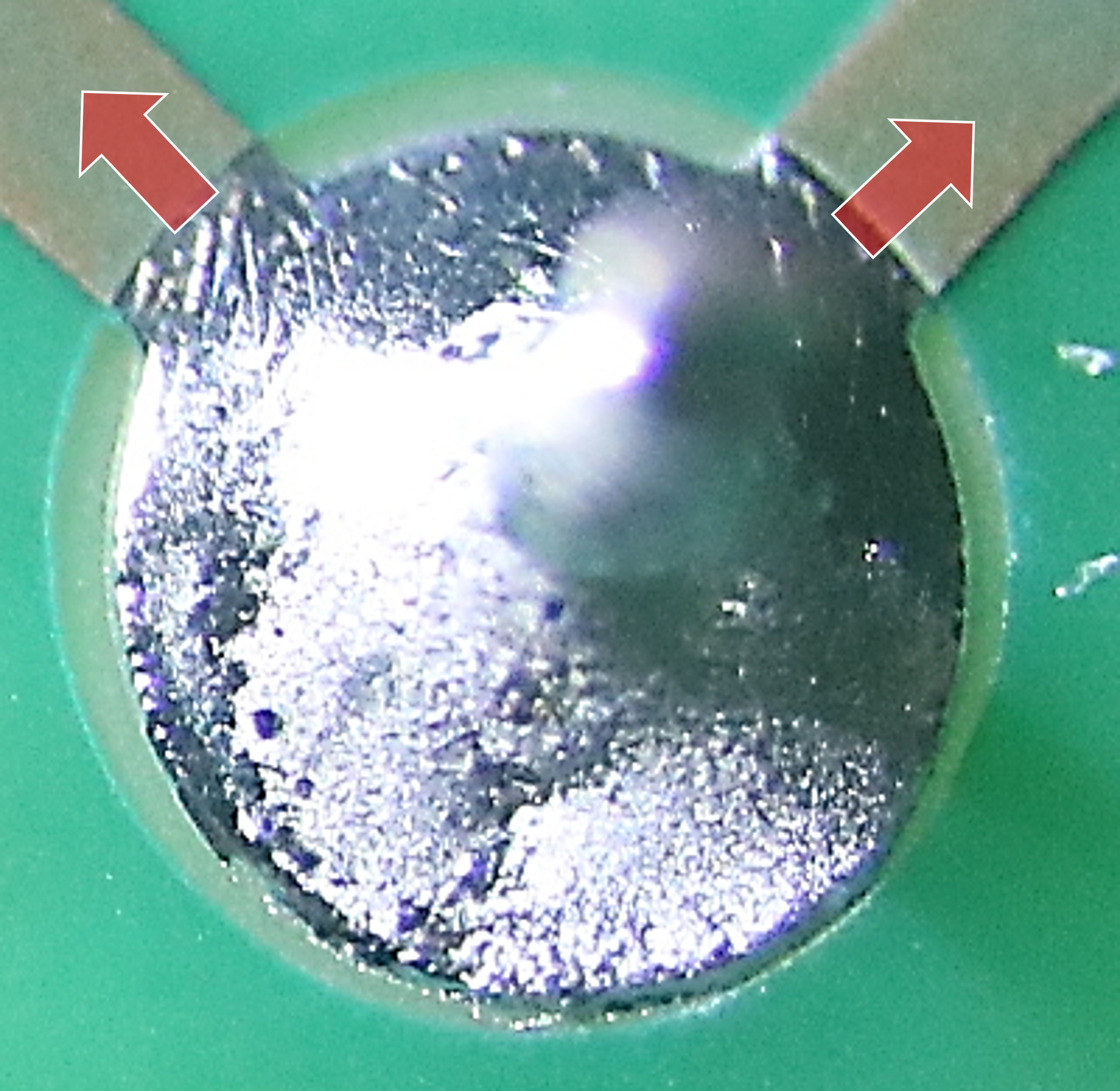

View of the inner structure using the common process including an abrupt removal of the heat-source.

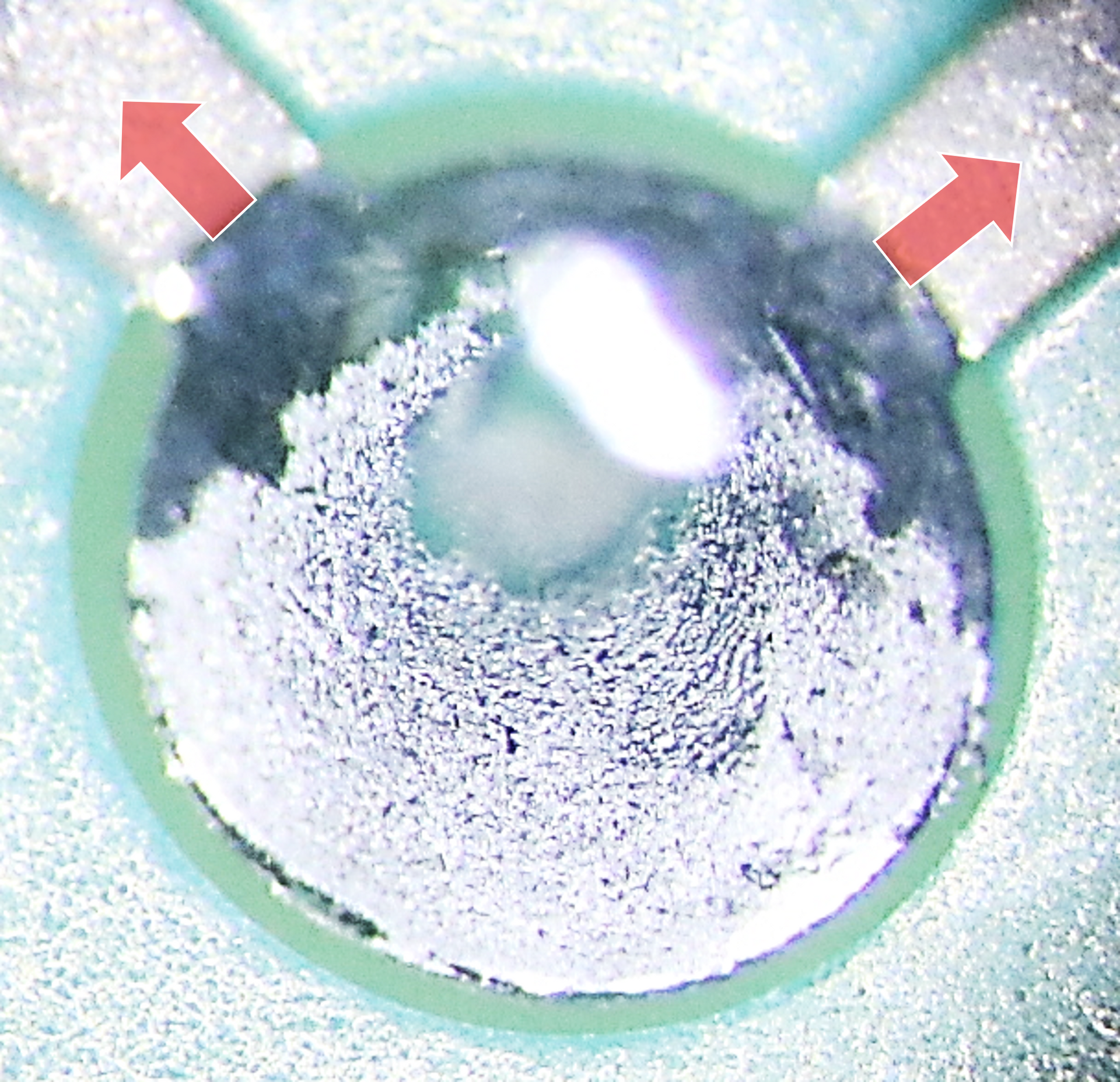

View of the inner structure after well performed Heat-Lifting via Convergence Solder Pad.

Shrinkage

Direction

In Conjunction With Heat Dissipation

Beyond the observation

of volume dilatation itself,

we now consider a definite

direction of the shrinkage

since there are directed

and dominant ways

respective heat dissipation.

There is a convergent cooling of the solder on the left hand, appropriate to a directed heat dissipation via adjacent conductive paths.

The shrinkage increases on the opposite side, where the high heat saturation of the pin also becomes apparent, causing a disorderly cooling and the rough and granular texture on the right hand.

Granulation

Hard To Retrace

With highly resolving

and detailed sequences,

we redefine causation of

granulated solder joints,

by convention and spuriously,

being traced back

to solder composition.

Observing the cooling-process, a granulation occurs, where the solder cools down disordered and abruptly, with no definite direction.

Sn95.8Ag3.5Cu0.7

Sn95.5Ag3.8Cu0.7

Sn96.5Ag3.0Cu0.5

Subsidence

Also Based On Thermodynamic Impacts

The very high replicability

of a certain defect is

opposed to prevalent

attempts to explain,

mainly based on outgassing

and sudden flux evaporation.

A subsidence occurs, where more than two opposite cooling- and shrinkage directions collide.

The heat dissipation via the pin finally potentiates the number of shrinkage directions.

Sn63Pb37

Alloy

Test Bench

Primacy To One Principle

Considering the new

while using our subject,

operations throughout

open out into convincing

success and quality

regardless an arbitrary

range of solder alloys.

Sn96.5Ag3.0Cu0.5

Sn63Pb37

Sn95.8Ag3.5Cu0.7

Sn99.3Cu0.7

Sn95.5Ag3.8Cu0.7

Results Comparative

Repeatability

On The Test Bench: The State Of The Art

Demonstrating the

repeatability of soldering-

defects and results,

depending on design and

associated heat dissipation.

Comparing two different designs, the results show congruent

appearances, with a high degree of regularity in the solder

structure in the area of directed heat dissipation(red arrrows).

Heat dissipation opposite

to 90 degree angle.

Heat dissipation opposite

to 180 degree angle.

Neuer Text